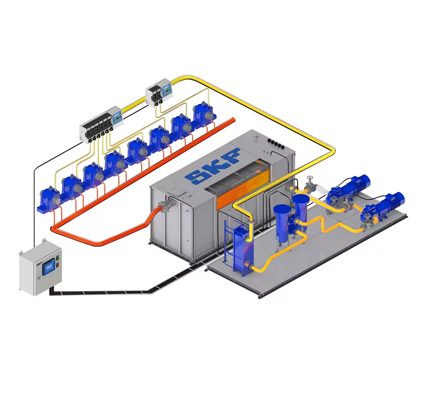

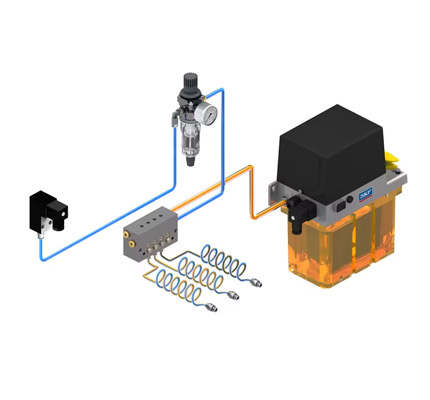

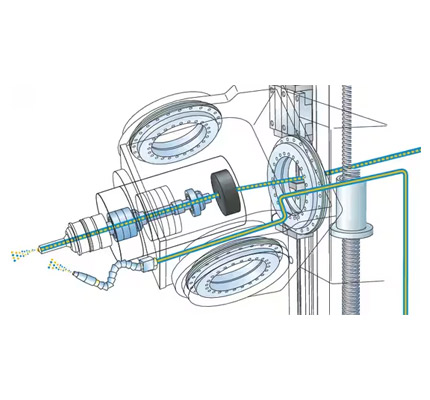

The right lubricant, in the right quantity, at the right time, to the right lubrication point.

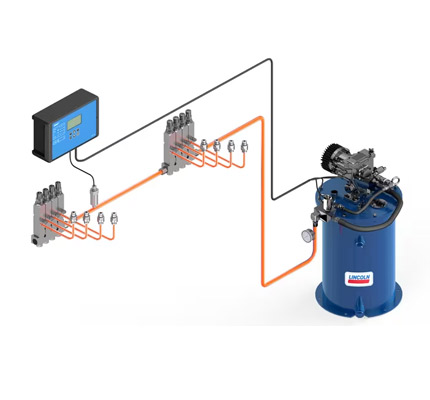

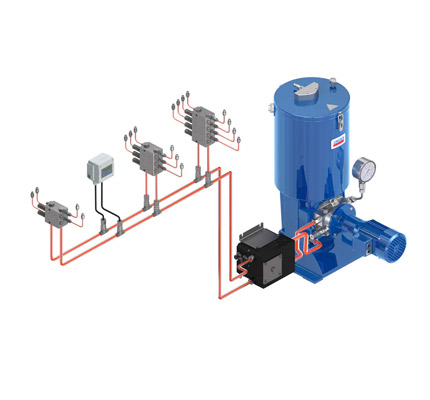

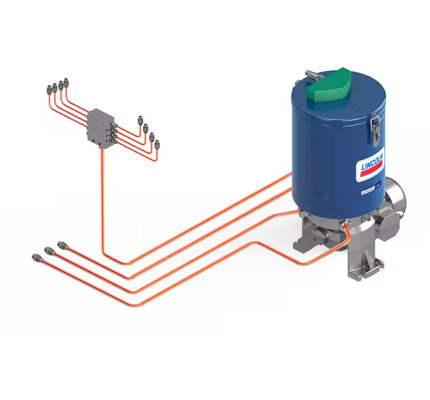

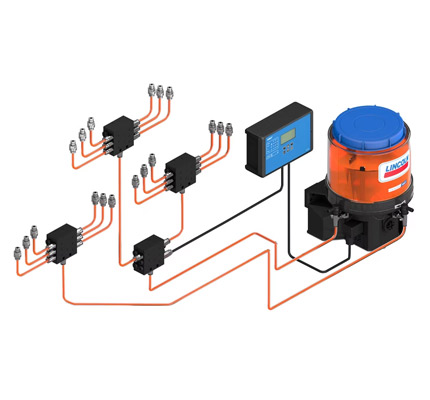

Centralized automatic lubrication systems are an effective way to increase machine availability while reducing reliance on scarce talent.

These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and machinery service life.

Designed to lubricate individual machines or complete plants, automatic lubrication systems provide proper, precise lubricant replenishment to all required points, enabling a range of benefits in the process.

Applications

- Machine tools

- Automation

- On/Off-road machines

- Construction, agriculture and forestry machines

- Mining and cement industry

- Food and beverage

- Railroad applications

- Steel industry

- Pulp and paper

- Wind energy

Benefits

- Significant savings in repair and spare costs

- Increased machine reliability

- Up to 50% savings in lubricant costs due to accurate timing and dosing of lubricants

- Fewer shutdowns and production losses

- Reduced environmental impact

- Greater workers' safety

Rotating equipment performance

Are you getting 100% from your equipment? Address your specific performance needs through our wide assortment of products, technologies, services and flexible new business models

Generalized Bearing

Life Model (GBLM)

Choose the right bearing for the right application, every time. The GBLM lets SKF customers and distributors calculate whether a hybrid bearing will outperform a steel one in a given application – or not.