Rotating equipment performance

Are you getting 100% from your equipment? Address your specific performance needs through our wide assortment of products, technologies, services and flexible new business models

Generalized Bearing

Life Model (GBLM)

Choose the right bearing for the right application, every time. The GBLM lets SKF customers and distributors calculate whether a hybrid bearing will outperform a steel one in a given application – or not.

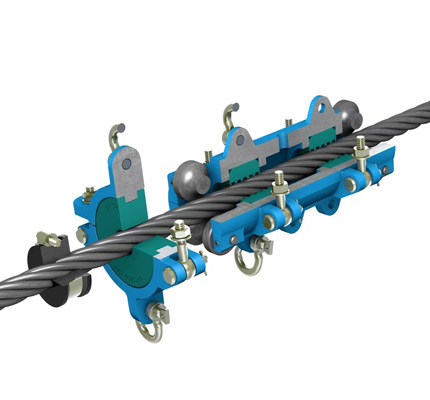

To increase wire rope life and reduce lubrication time.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes.

Lubrication intervals should be determined according to rope manufacturer specifications.

The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated.

Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available.

The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires.

Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Features and benefits

- Reduces friction

- Protects against corrosion

- Enables lubricant to adhere to each wire and penetrate to the core for long-lasting protection

- Fast and efficient – reduces lubrication time by up to 90% vs. manual lubrication

- Increases operator safety

- Protects the wire ropes

- Reduces waste and contamination

- Robust design for harsh environments

Applications

- First choice for applications in marine, oil and gas or steel industry

- Traveling cranes, wharf cranes, ship cranes, mobile cranes

- Deck winches, ship hoists

- Winding machines in open pit mining

- Oil and gas rigs

- Ropes

- Chair and ski lifts

- Elevators

- Drag ropes

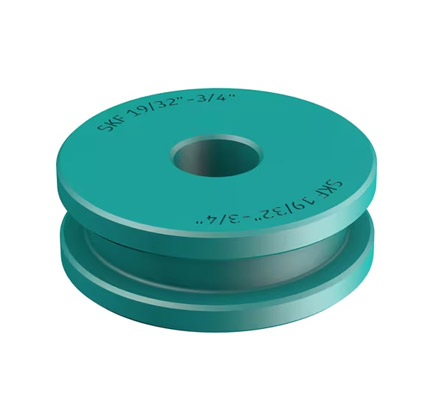

Groove cleaner

Designed to complement the Lincoln wire rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life.

Each groove cleaner is produced individually based on rope specifications to make sure that the device profile matches accurately with the strands.

The groove cleaner unit consists of a groove cleaner device, as well as separating bushings and a separating bushing support to minimize wear. The cleaner is manufactured from thermoplastic polyurethane elastomer (TPU) for durability.

Lubrigun air-operated piston pump

Available for all common drum sizes, the performance-proven Lubrigun pump features a powerful displacement air motor. Its lightweight, zinc head casting resists corrosion, and its double-acting design provides high pressure and uniform delivery on both up and down strokes.

How to order a complete wire rope lubrication system?

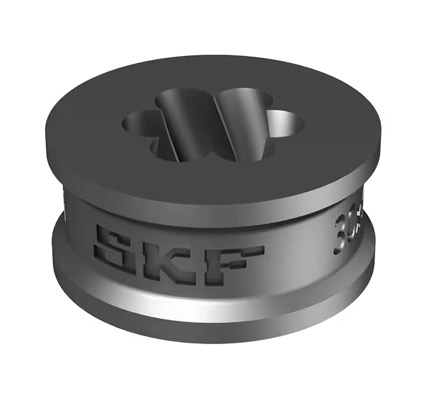

- Select seal and roll kit to fit the wire rope diameter.

Interchangeable kits include seals and rolls to fit wire rope diameters in their respective size ranges. - Choose wire rope lubricator body or bodies to fit the seal and roll kit selection.

- Select pump and accessory package to fit the required grease container size.

- Choose the separating bushing that fits with the nominal diameter of the wire rope.

- The separating bushing is fastened by the support. This is common for all the separating bushings.

- The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope specification, or send a sample. To provide an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included).